- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

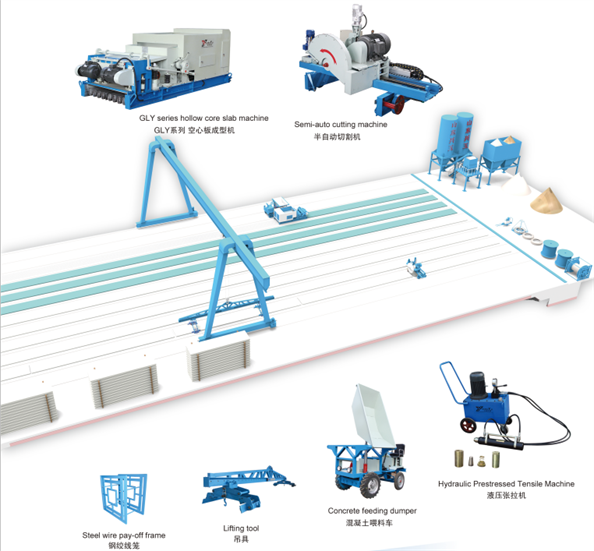

Factory layout:

Description of Concrete Feeding Dumper

It is specially designed by our researchers for GLY prefabrication slab machine, width a feature of side turn down to for concrete directly into the hopper of the shaping mill, decreasing labor force with easy and convenient operation, a necessary device for floor slab manufacturers.

![]()

The Manual Cart for Concrete feeding is use to unload the concrete in the extrusion machine hopper. The Battery Operated Mini Dumper is driven directly below the mixer of batching plant for collection of the concrete mix. As the bucket is mounted on back side of the vehicle one can view & control while unloading concrete mix into the hopper of extrusion machine.

The Manual Cart for Concrete feeding is use to unload the concrete in the extrusion machine hopper. The Battery Operated Mini Dumper is driven directly below the mixer of batching plant for collection of the concrete mix. As the bucket is mounted on back side of the vehicle one can view & control while unloading concrete mix into the hopper of extrusion machine.

Generally there are 2 dumpers operated in the circuit to make sure that the extrusion machine doesn't run dry of concrete mix.

The Mini Dumper operates on Battery that has a power capacity of 5.5 kw, bucket capacity of 0.3 cubic metric & rotational speeds of 2600 rpm.

Manual Concrete Feeding Carts is operated manually by a single man; it is having unloading from only 1 side.

| Type |

Load weight (KG) |

Power (kw) |

rotation rate (r/min) |

Volume of hopper (m3) |

Machine weight (KG) |

Picture of machine |

|---|---|---|---|---|---|---|

| XY-3 | 600 | 5.67 | 2600 | 0.3 | 670 |

|

| XY-7 | 1500 | 11 | 2000 | 0.7 | 1100 |

|

This feeding machine is specially designed by our researchers for prefabrication slab machine, wuth a feature of side turn down for concrete directly into the hopper . It highly decrease labor force with easy and convenient operation, a nessary device for slab manufactures.