- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

Prestressed, Precast Concrete Hollow Core Light / Heavy Duty Boundary Wall Panels.

Prestressed, Precast Concrete Hollow Core Light / Heavy Duty Boundary Wall Panels.

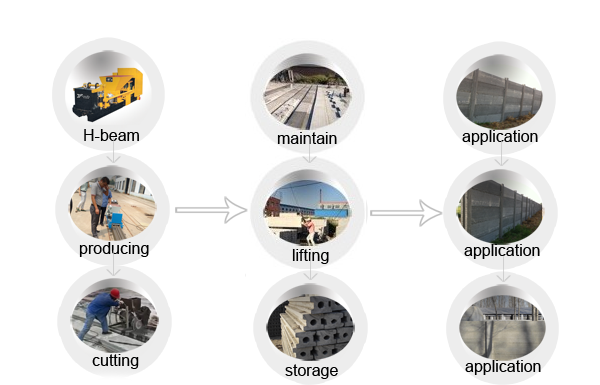

Pre-stressed Precast concrete Hollow core Boundary wall or Compound wall & Supporting ‘H’ column are made by Concrete Extrusion machine & reinforced with Carbon steel wires, which works without the need of any Mould or Form work for production.Pre-stressed Precast concrete Hollow core Boundary wall or Compound wall & Supporting ‘H’ column are made by Concrete Extrusion machine & reinforced with Carbon Steel wires, which works without the need of any Mould or Form-work for production.

H-beam machine:

Advantage:

Brick walls is time consuming to erect and costly to keep maintaining. Our Pre-stressed Precast concrete Hollow core Boundary wall or Compound walls overcome these handicaps of traditional brick walls.

Extrusion of Boundary wall slab / panel is 5 times Faster, Easier & Most Economical solution for production compared to the conventional Technique of individual panel cast-in-site.

Extrusion speed of the machine for the Light-duty Boundary wall slab is between 1.8 to 2 meters per Minute with a limited labour force. (i.e. it extrudes in one minute one panel of 7 feet).

Being Hollow it’s self-weight is reduce, saves on concrete weight & thus save money with same load bearing capacity as compared with cast-in-situ.

Our Precast Concrete Boundary walls are made/ erected with the help of Supporting ‘H’ column / posts erected directly into the ground which have grooves to accommodate Boundary wall slabs / panels.

This can be also installed vertically without post as a boundary wall or cold storage rooms or industrial sheds, Pre-fabricated mezzanine floors etc.

Parameter of concrete fence wall machine:

| Sr. No. | Model | Size of Slab (mm) | Power (kw) | Weight / meter (kg) |

|---|---|---|---|---|

| 1 | ZB50-300-2 |

Thickness - 50 Width - 300 |

1.35 | 32 |

| 2 | ZB90-600 |

Thickness - 90 Width - 600 |

7.7 | 85 |

| 3 | ZB100-600 |

Thickness - 100 Width - 600 |

7.7 | 98 |

Parameter of concrete fence post machine:

| Sr. No. | Model | Size of Slab (mm) |

|---|---|---|

| 1 | ZB150-150-2 |

Thickness - 150 Width - 150 |

| 2 | ZB180-280-2 |

Thickness - 180 Width - 280 |

We can design different type of concrete fence wall&post machine according to your requirements.

Producing Site of concrete fence wall&post machine:

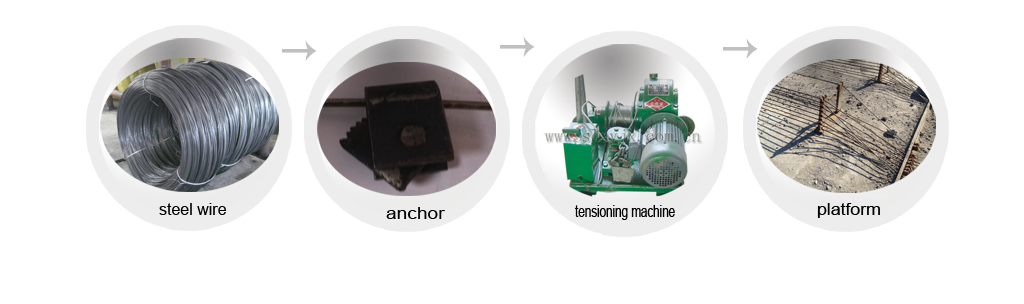

1. Prestressed concrete fence wall&post producing bed prepare and tensioning.

1.1 Cleaning the producing bed:Clean the concrete residue on the producing bed with special tools and make the platform surface clean, smooth.

1.2 Painting parting agent:The adopted parting agent must be up to the required standard without harmful

chemical substance.

1.3 Distribute the steel wire.Steel wire of low relaxationand stress relieving is adopted .

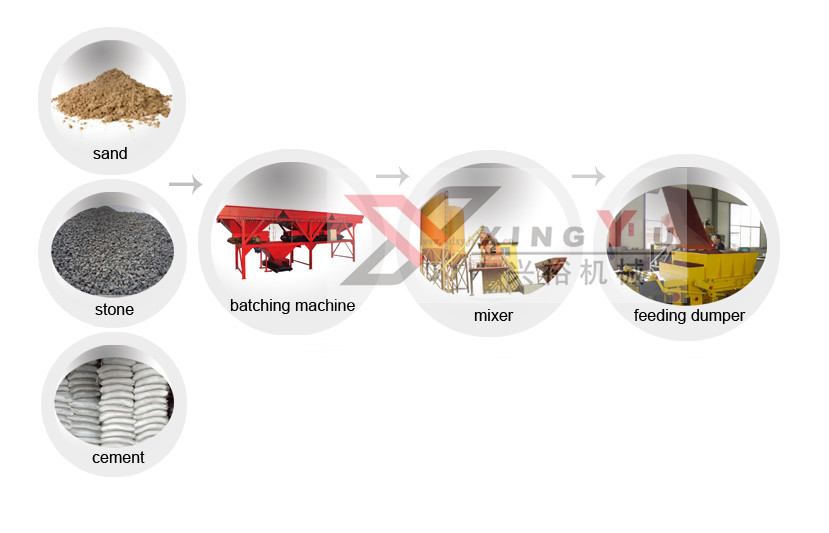

2. Precast concrete fence wall&post materialcompositions and quality standard

1.1 Cement:32.5R or 42.5R Portland cement and ordinary Portland cement

1.2 Sand:Medium sand

1.3 Stone:Rubble and broken pebble are optional

1.4 Water:Drinking water without harmful substance

1.5 Dry concrete is used for precast concrete fence wall&post with a strength grade of C30 or C40.

3. Prestress concrete fence wall&post technological flow

Cleaning the producing bed→ painting parting agent→ distribute steel wire and fix→tensioning the steel wire→ mix and transportation of concrete → slab molding →make testing block→ covering and curing →testing block intensity →relief the steel wire→ cutting slab→ storage

We can design and manufacture all kinds of concrete forming equipment according to customer's demands. Meanwhile we also can provide our customers a complete set of technology and solution for all producing flow.