- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

Summary

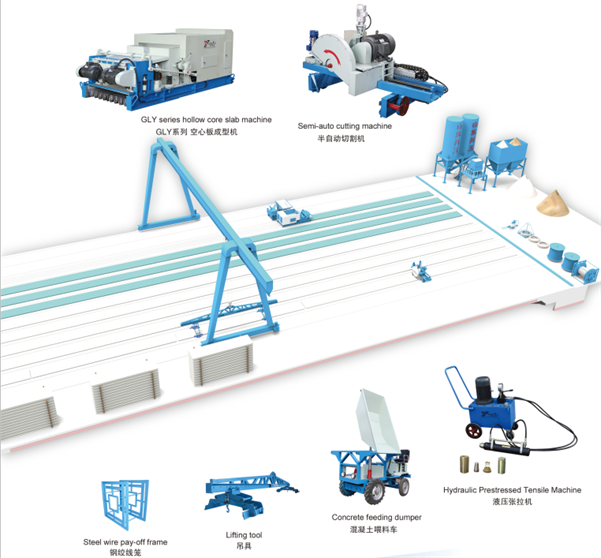

Prestressed concrete core slab machine is designed reasonable in structure, easy for operation and maintenance, durable with high speed productivity, by which cored slabs produced are smooth in surface, compact in high intensity. Random cutting for any length (according to standard), flexible combination of the slab can satisfy various kinds of floor construction. With prestress cored slabs construction framework can be simplified, bearing walls and beam columns are reduced, floorage increased and construction cost decreased

Prestressed reinforcement should be under relaxation and stress relieving with a performance up to the national standard.

During production prestressed reinforcement is to be placed on the platform first and stretchingis done on it according to the standard, then adjust the plug extruder in readycondition, feed the necessary concrete into the hopper of the extruder, after aprocessing of consolidation and high frequency jolt ramming, cored slab is come into being and through curing, gradual tension force relief, the slab can becut into desired size and stored.

Hollow core slab machine works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to form the concrete hollow core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY serious concrete hollow core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

Advantages

1、One machine can make one slab, low investment

2、Smooth surface, high-density structure

3、Simple structure, easy operate

4、Long working life with few wearing parts

5、The slab length can be 4.2m to 18m

Testing spot

Producing Site and Testing Spot

1. Prestressed hollow core slab producing bed prepare and tensioning.

1.1 Cleaning the producing bed:Clean the concrete residue on the producing bed with special tools and make the platform surface clean, smooth.

1.2 Painting parting agent:The adopted parting agent must be up to the required standard without harmful

chemical substance.

1.3 Distribute the steel wire.Steel wire of low relaxationand stress relieving is adopted .

2. Prestressed hollow core slab material compositions and quality standard

1.1 Cement:32.5R or 42.5R Portland cement and ordinary Portland cement

1.2 Sand:Medium sand

1.3 Stone:Rubble and broken pebble are optional

1.4 Water:Drinking water without harmful substance

1.5 Dry concrete is used for prestress hollow core slab with a strength grade of C30 or C40.

3. Prestress hollow core slab technological flow

Cleaning the producing bed→ painting parting agent→ distribute steel wire and fix→tensioning the steel wire→ mix and transportation of concrete → slab molding →make testing block→ covering and curing →testing block intensity →relief the steel wire→ cutting slab→ storage

We can design and manufacture all kinds of concrete forming equipment according to customer's demands. Meanwhile we also can provide our customers a complete set of technology and solution for all producing flow.