- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

Concrete purlin machine factory layout:

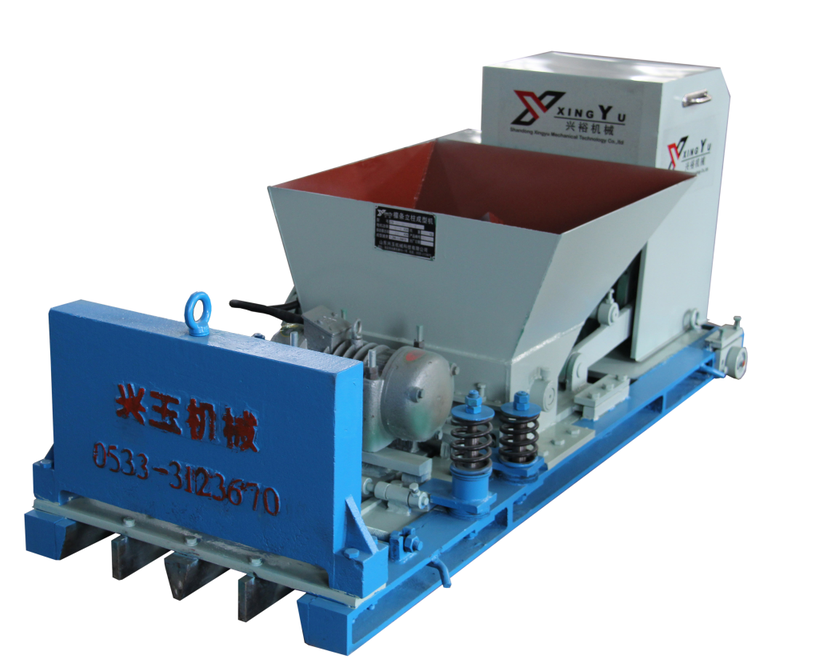

Description Of Concrete Purlin Machine:

Prestressed purlin forming machine is a specialized construction machine developed in our company according to the actual situation of the nation with characteristics of novelty design, reasonable structure, easy operation, high efficiency and endurance. The purlin for construction produced with this machine is characterized with high intensity and accurate size completely meeting the national standard. Equipped with this machine is a lifting and moving system which is flexible and easy for assembly and dismantle, and satisfying the customer.

Components

Chassis, driving system, feeding material system, vibrating system, press plate system, system,

risefall and travel system, electrical control system.

Advantages

1、One machine can make one slab,low investment

2、Smooth surface, high-density structure

3、Simple structure, easy operate

4、Long working life with few wearing parts

Producing Site of precast concrete purlin machine :

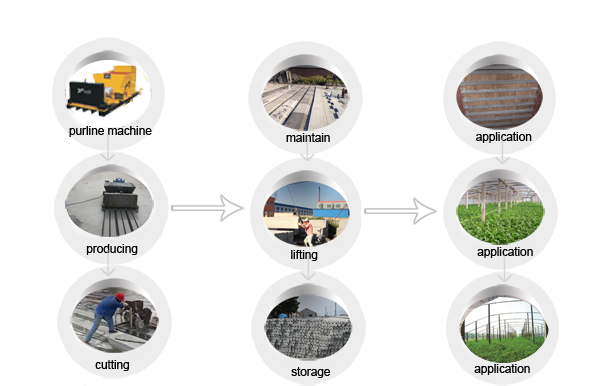

Application:

Parameter of concrete purlin machine:

| Product name | Type | Productivity |

|---|---|---|

| Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min |

| Concrete purline machine | 60*120*140*4 | 1.3-1.5m/min |

| Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min |

| Concrete purline machine | 70*140*160*2 | 1.3-1.5m/min |

| Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min |

We can design differents types of precast concrete pillar machine according to your requirements.

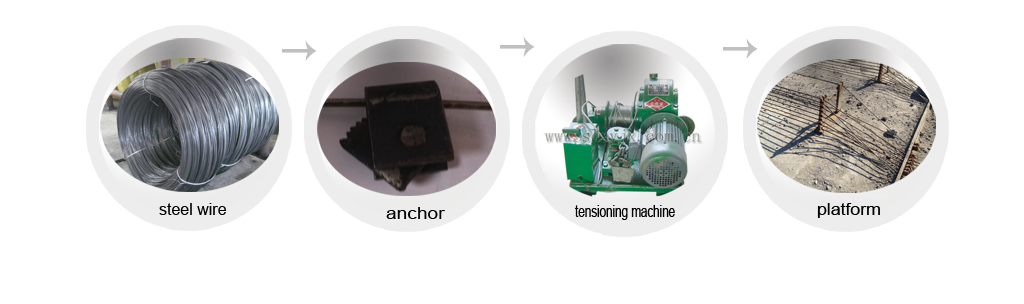

1. Precast concrete purlin producing bed prepare and tensioning.

1.1 Cleaning the producing bed:Clean the concrete residue on the producing bed with special tools and make the platform surface clean, smooth.

1.2 Painting parting agent:The adopted parting agent must be up to the required standard without harmful

chemical substance.

1.3 Distribute the steel wire.Steel wire of low relaxationand stress relieving is adopted .

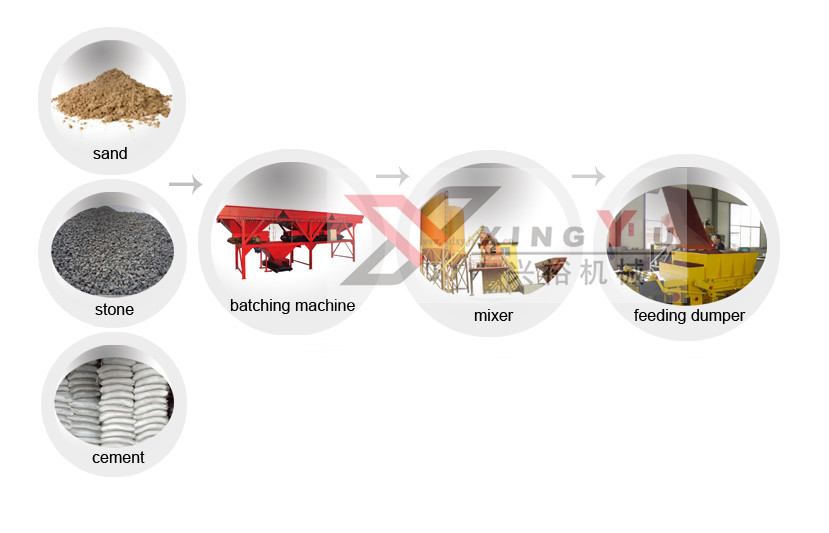

2. Prestressed concrete purlin material compositions and quality standard

1.1 Cement:32.5R or 42.5R Portland cement and ordinary Portland cement

1.2 Sand:Medium sand

1.3 Stone:Rubble and broken pebble are optional

1.4 Water:Drinking water without harmful substance

1.5 Dry concrete is used for precast purlin material with a strength grade of C30 or C40.

3. Precast purlin technological flow

Cleaning the producing bed→ painting parting agent→ distribute steel wire and fix→tensioning the steel wire→ mix and transportation of concrete → slab molding →make testing block→ covering and curing →testing block intensity →relief the steel wire→ cutting slab→ storage

We can design and manufacture all kinds of concrete forming equipment according to customers'demands. Meanwhile we also can provide our costomers a complete set of technology and solution for all producing flow.