- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

Main product standard and features

1. HQJ lightweight wall panel machine is the main equipment of making hollow core lightweight wall panel.

Work with special cutter, mixer, dumper and crusher, using screw extrusion method to make the hard dry concrete moulding rapidly. It have the advantage of easy operate, high efficient, stable quality.

This equipment is automatically continuous produce, we can chose different size machine according to our requirements. The productivity is 1.4m-1.8m/min.

2. Hollow core lightweight panel

This kinds of hollow core slab have two layers of steel wire(φ1.6~3 mm low carbon steel sire) as strength material instead of alkali resistant glass fiber. The wall panel structure has the advantage of high stiffness, uniformity thickness, good flatness, precisely size, reduce the randomness in operation, mix with different materials, meet different requirement, advanced technology, high density to anti external force. The wall panel has light weight to increase the impact resistance and anti-seismic effect. This solved the problem of slab crack. There is no need to use steam curing for this slab, forming at one time. It is a new type building material.

According to national standard the width of HQJ lightweight material is 600mm, it also can change the width according to building requirement. The standard thickness is 80mm, 90mm, 100mm, 120mm,150mm,180mm.The slab length can cut in a range of 1-4meters according to different building structure.

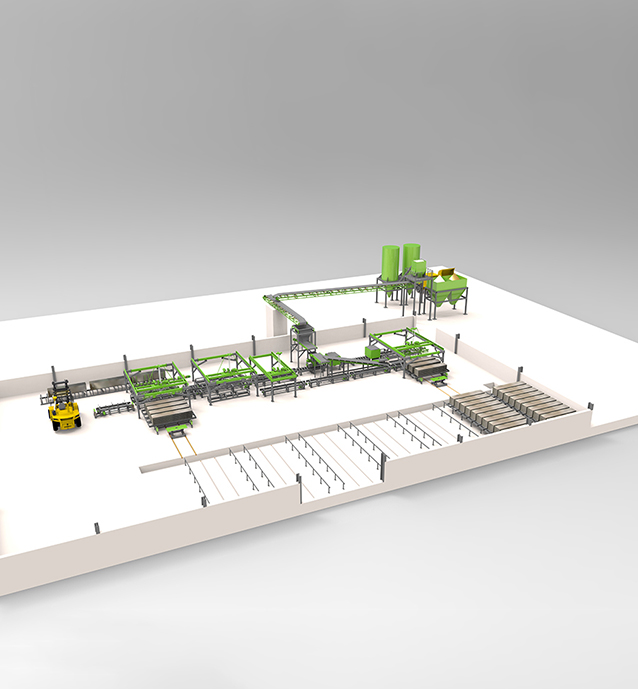

3. Supporting equipment

The supporting equipment of HQJ lightweight material are mixing plant, cutter, dumper, crusher, slab transporter, lifting tools and so on.

4. Other function

Except above product, we can also design drawing and build solutions of HQJ wall production line. Our engineer can supply technical service such as guide the infrastructure construction, train workers and technican, research ratio of different material.