- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

Brief introduction

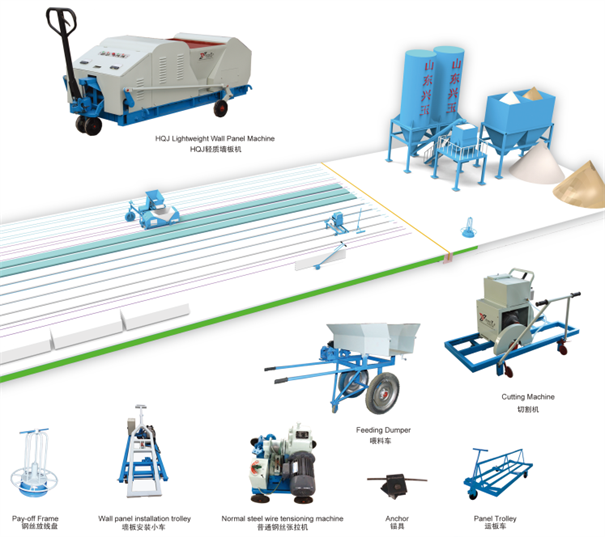

HQJ lightweight wall slab forming machine is a specialized machine to produce non-load bearing external wall slab, widely used for the external partition of building, such as office building, hotel and apartment. The slab produced with this machine is characterized with low cost, light weight and easy for assembly, meeting the standard of JG3060-1999 <Industrial Clinker concrete hollow core wall slab>.

Light weight wall panel machine adopts extrusion method. It use different kinds of lightweight materials, such as fly ash, slag, ceramsite, pearstone etc. The slabs have the advantage of smooth surface, lightweight and non-deforming after installation. It is a new-type non-loading bearing material with good fire prevention, moisture proof,good sound insulation, heat insulation used as partition wall board and exterior wall board. The easy wear spare parts. Annual output can reach 150000 square meters.

Structure:

HQJ lightweight wall slab forming machine is consisted of frame, gearing-down system, vibratory system, manual hydraulic lifting system, electrical system and shield .

Advantages

1、Extrusion method, smooth surface

2、One machine can make one slab,low investment

3、Simple structure, easy operate

4、Long working-life with easywear spare parts

5、Non-loading bearing partition wall board and exterior wall board.

6、Sound insulation, heat insulation

MACHINE SPECIFICATION

The width of panel produce is fixed to 600 mm. The length of panel is the desired Room height & most common thickness used is 90mm,but please note the thickness can vary from 75 to 150 mm depending on customer and need.

The edges in Front & Back face of panel are stepped down by 4mm x 30mm width, which is filled during plastering along with the side edges which are tongued and grooved, allowing aligning of panels to each other and making the wall stable and integral.

The speed of the machine is 1.5 to 1.8 meter per minute. The Main motor drives the especially designed gearbox which in-turns rotates augers / screws & synchronizes with the high frequency vibrators that are fitted on the spring-loaded plate. The intense vibration and pressure built within the machine mixes the concrete effectively and plasticized it against the side walls to form a dense hollow core concrete slab.

| No. | Model | Size of Slab (mm) | Power (kw) | Weight / Sq. Mtr. (kg) |

|---|---|---|---|---|

| 1. | HQJ80-600 |

Thickness - 80 Width - 600 |

6.3 | |

| 2. | HQJ90-600 |

Thickness - 90 Width - 600 |

8.5 | 53 |

| 2. | HQJ100-600 |

Thickness - 100 Width - 600 |

8.5 | 70.32 |

| 3. | HQJ120-600 |

Thickness - 120 Width - 600 |

6.6 | 85.99 |

Theoretical Weight of Panels:

Conventional Concrete having density of 2,000 kgs / m3 The weight of panel size of 90mm Thick X 600mm Wide is around 71 Kgs / meter square & for 2740mm (9 feet) long is 195 Kgs.

Light Weight Concrete for Concrete Mix of 1,800 kgs / m3 while using Foundry slag, The weight of panel size of 90mm Thick X 600mm Wide is around 64 Kgs. / meter square & for 2740mm (9 feet) long is 175 Kgs.

Light Weight Concrete for Concrete Mix of 1,500 kgs / m3 while using LECA of 4 to 8mm size. The weight of panel size of 90mm Thick X 600mm Wide is around 53 Kgs. / meter square & for 2740mm (9 feet) long is 146 Kgs.

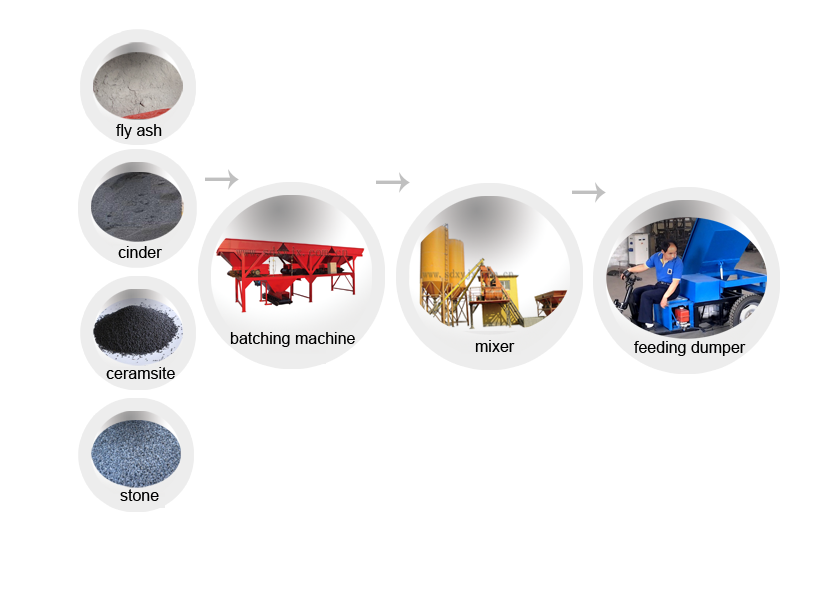

1 Prestressed lightweight wall panel materialcompositions

It use different kinds of lightweight materials, such as fly ash, slag, ceramsite, pearstone , sand etc.

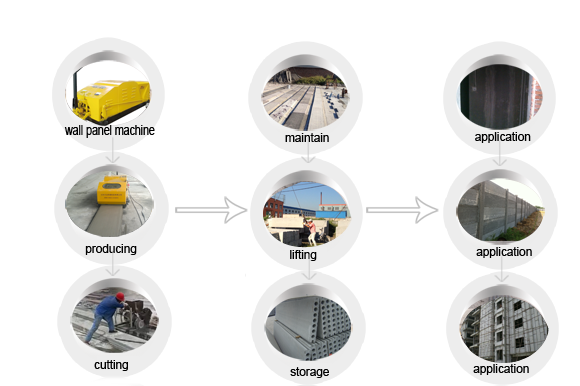

2. Prestress lightweight wall panel producing flow

Principle:The main motor transmit power to the reduction gearbox through V-shape belt pulley so as to make the spiral reamer turn in the forming space consisted of frame, vibrator and pedestal. While working, The spiral reamer turns according to the the given rotary direction in the forming space, continuously delivering the mixed materials in the hooper to the forming space, with the both screaming strength from the spiral reamer and vibrating force from the vibrator, the materials are being squeezed into compaction, and at the same time also the anti-force is also produced on the turning reamer so that the extruder keeps forward to form the concrete into the slab. Through the molding scraper in the rear part of the machine, polish the surface of the slab smoothly to meet the requirements.

We can design and manufacture all kinds of concrete forming equipment according to customer's demands. Meanwhile we also can provide our customers a complete set of technology and solution for all producing flow.