- HOME

- Company

- Products

- Solutions

- Latest Post

- FAQ&Service

- Contact Us

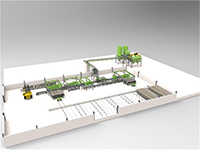

We can provide engineer to install and debug machines for you. If you do not need this, we can also send detailed videos for your reference, also we can provide you detailed technical drawings and guidance for your production site planning and platform construction. Read More>>

"XINGYU" Precast Plant & Machinery are Exported to Russia, UZ, Saudi Arabia, Middle East, Malaysia, Thailand, India, Indonesia, Bangladesh, Bhutan, Philippines, South Africa, Nigeria, etc Read More>>

The technical supporting all the timeThe technical supporting all the ... Read More>>

One year warranty for whole machineOne year warranty for whole machine... Read More>>

Free quick wear partsFree quick wear partsFree quick wear partsFree qu... Read More>>

Free training to end-usersFree training to end-usersFree training to e... Read More>>

light weight, high strength, sound insulation, heat insulation, damppoof, fireproof, smooth surface, easy to transport, easy to install, bea...

MORE

Precast concrete elements extrusion machines adopts gravity extrusion method....

MORE

Hollow core slab machine works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing w...

MORE

Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibra...

MORE

concrete pole making/molding machine, concrete fence extruder,concrete boundary wall...

MORE

Prestressed Concrete Purline Machine Is Our Special Developed Products As Results Of Our Engineers Research, With Which 60%Steel Material Wi...

MORE

Prestressed purlin forming machine is a specialized construction machine developed in our company according to the actual situation of the n...

MORE

Prestressed Concrete lintel Machine Is Our Special Developed Products As Results Of Our Engineers Research, With Which 60% Steel Material Wi...

MORE

t beam for construction produced with this machine is characterized with high intensity and accurate size completely meeting the national st...

MOREWe only focus on the precast concrete industry Shandong Xingyu Mechanical Technology Co.,Ltd, located in Zibo City, specialized in concrete prefabrication machine manufacture with a name brand of 'Xingyu'. We also founded "zibo Concrete Prefabrication Machine Reasearch Institute" with Shandong Science and Technology University in 2007, and have successfully developed the non-circular hole slab forming machine and the prestress... more>>